Construction solutions for Terawatt-scale solar

Utilizing our full suite of digital and solar construction automation solutions built on decades of expertise, Terabase enables partners to build reliable plants faster and within budget, while enhancing predictability and optimizing long-term performance.

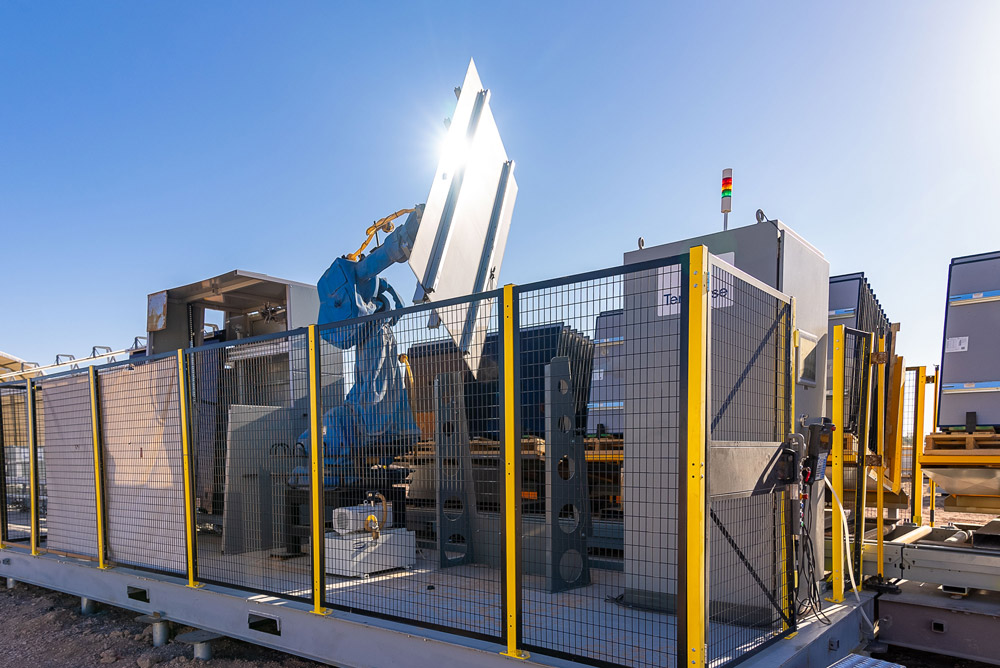

Terafab

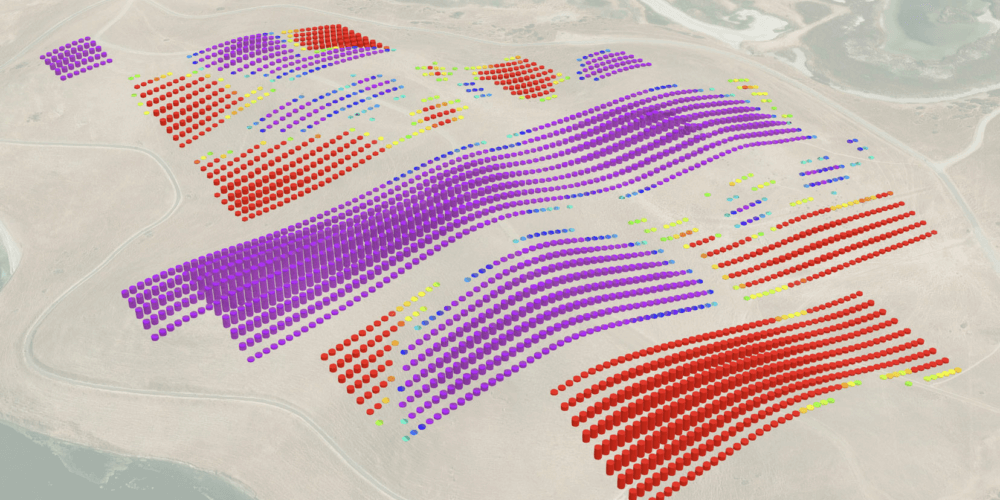

Terafab™ transforms solar power plant construction with a modern in-field factory approach, allowing partners to build more with less and expand the number of projects they deploy simultaneously. Watch the video of our first commercial deployment.

- World’s first automated, digital field factory for PV module and tracker assembly

- Improves efficiency through high throughput, 24/7 operation, and modularity

- Increases installation productivity by a factor of 2x over traditional methods

- Eliminates the physical safety risk of construction workers needing to lift heavy solar panels and steel structure

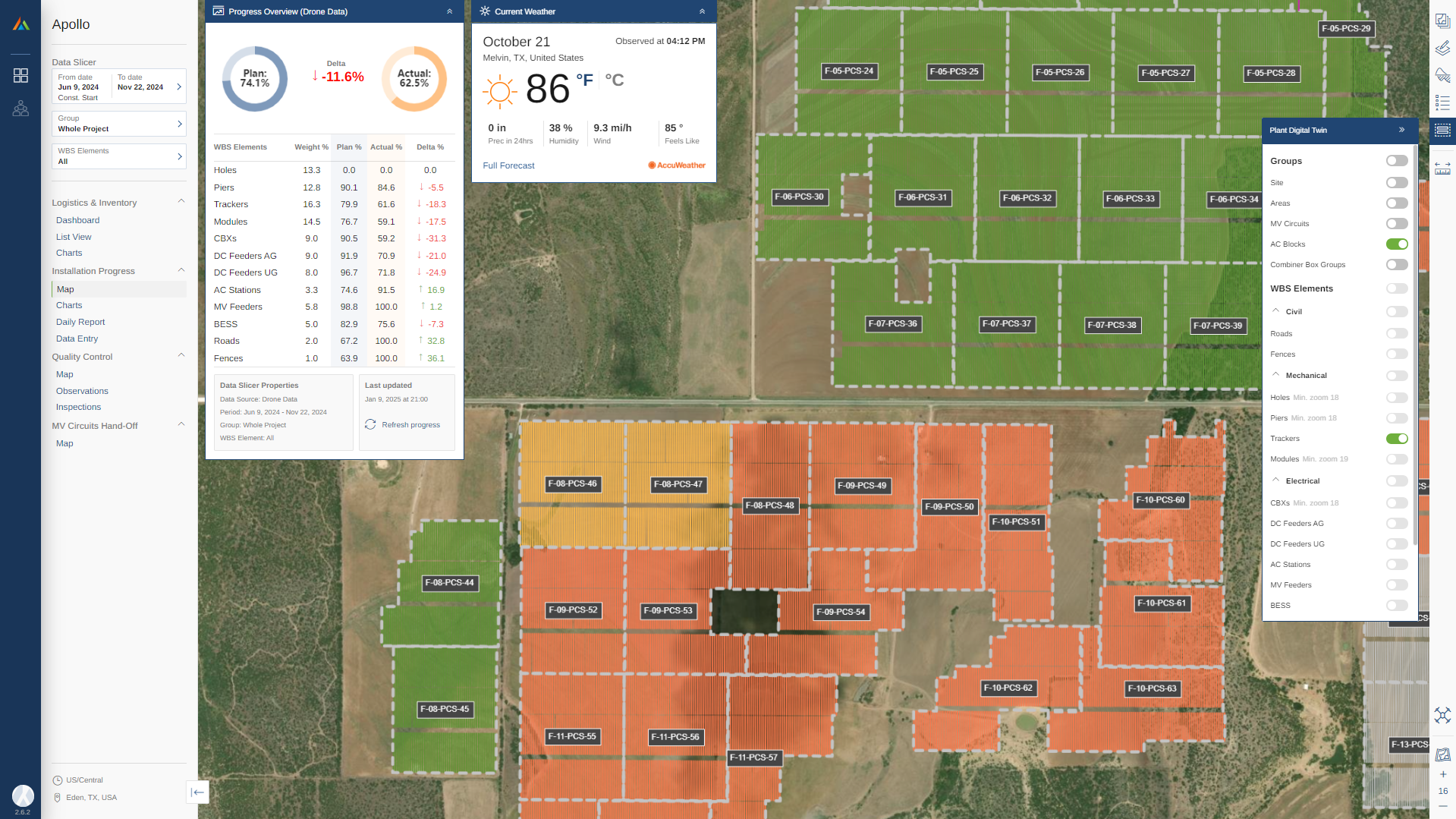

Construct

Construct is a cloud-based construction management and quality control platform designed from the ground up for utility-scale solar projects. The solution has supported more than 16+ GW of projects from leading owners and EPCs.

- Mitigate project risks

- Reduce project management overhead

- Enhance build quality

- Expedite construction

- Improve communication with key stakeholders

Enhance your solar project with Terabase

Learn more about leveraging our technology and expertise through every phase of your utility-scale solar project.